VOWAbond+ - Optional Extensions

With VOWAbond+ we enable customers to further refine our products individually by lamination, perforation or HF welding. Thanks to our in-house facilities we achieve a fast and efficient production process with optimum quality. Roll-by-roll finishing is possible for stock items, and the usual minimum quantities apply for customer-specific order goods.

Living

Automotive

Boat- and Shipbuilding

Healthcare and Medicine

Sports and Fitness

Contract

Small Leather Goods

Table Protectors

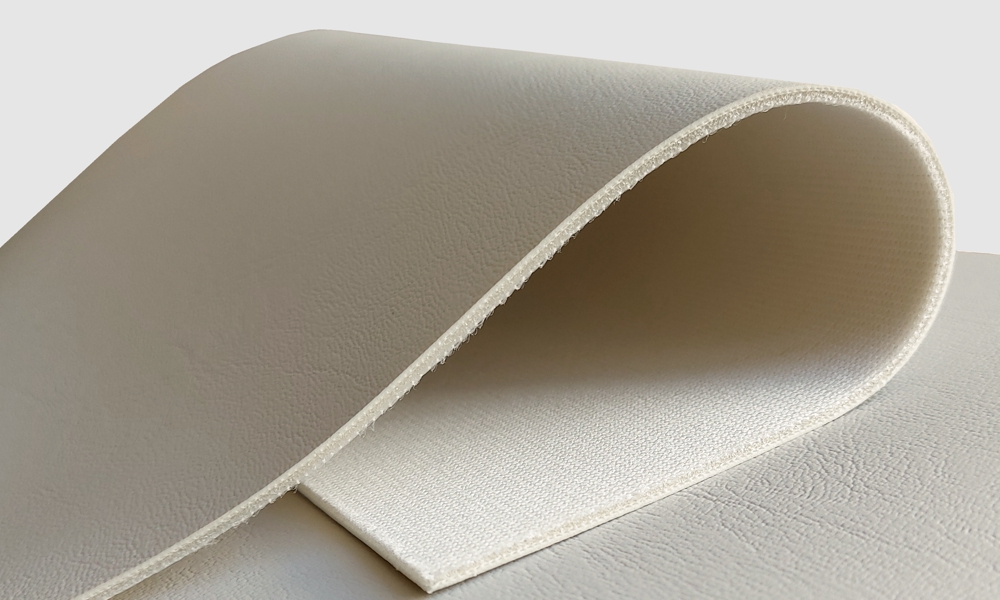

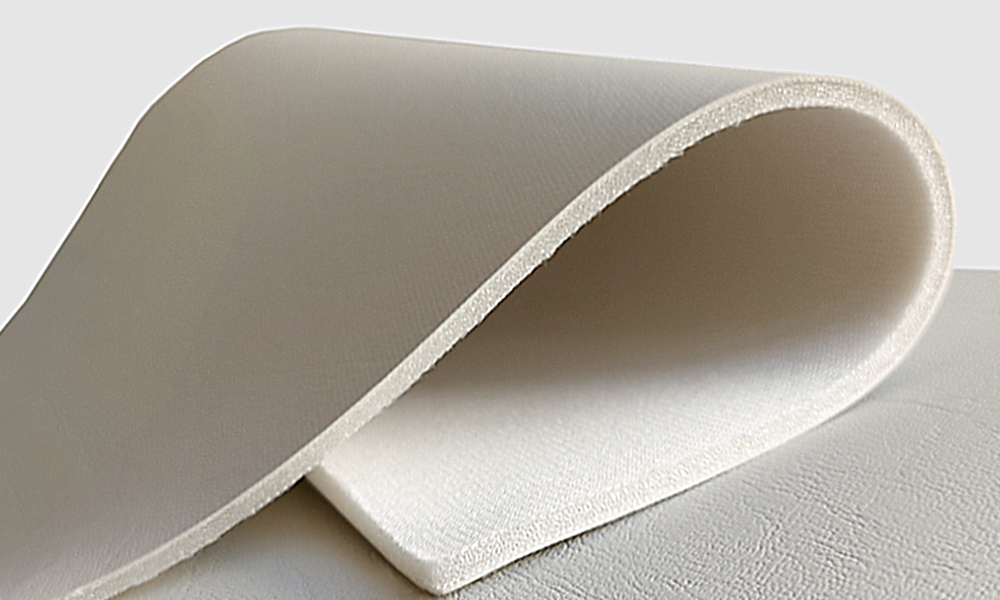

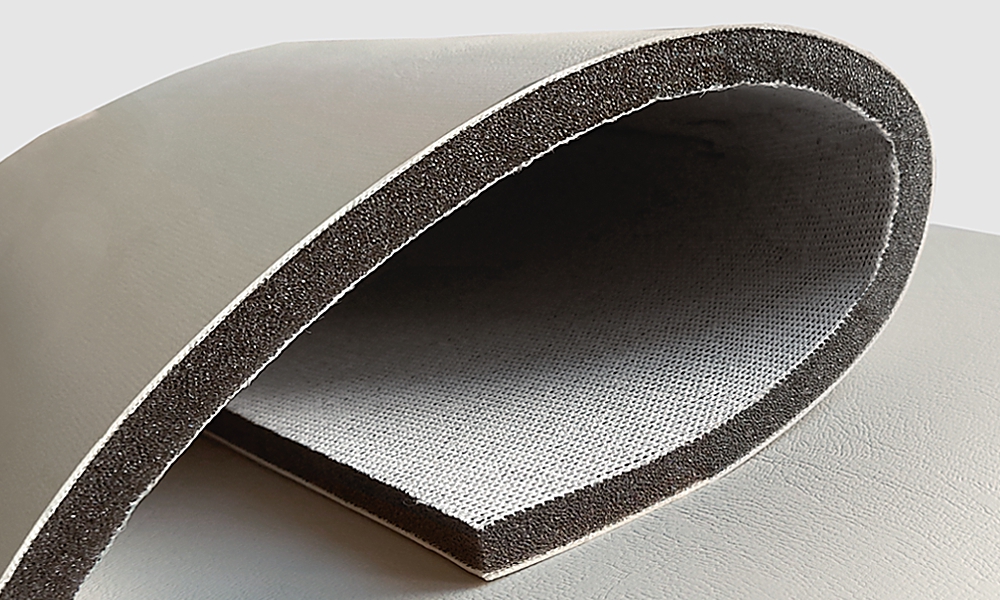

Laminations

Our profile

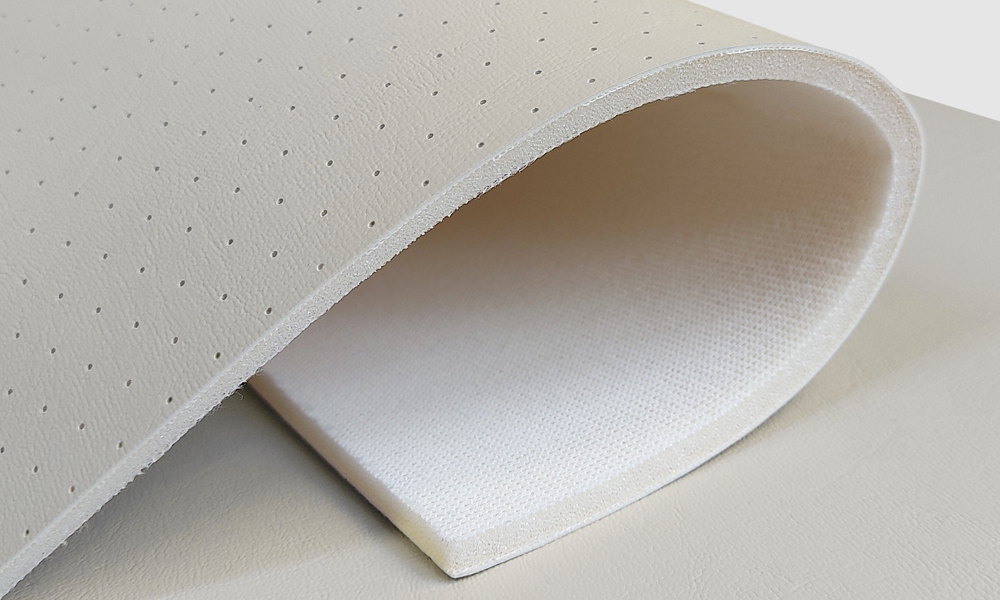

As a major specialty and niche producer of coatings in Europe, we offer a wide range of products that is ideally complemented by our in-house flame lamination. We have the possibility to produce imitation leather and then laminate it afterwards on our own facilities to achieve an optimum material composite.

Custom lamination

Are you looking for a reliable partner to laminate your individual product? We have decades of know-how in dealing with customers' own materials and will work closely with you to develop your desired, customized product.

Individually adaptable: foam thickness, shore hardness, density

With our in-house flame lamination, we can laminate almost our entire stock portfolio roll by roll and offer it with a wide variety of foam thicknesses and qualities. Colour, density and shore hardness are specifically adapted to the unique requirements. Here is a small selection of the most common foam thicknesses:

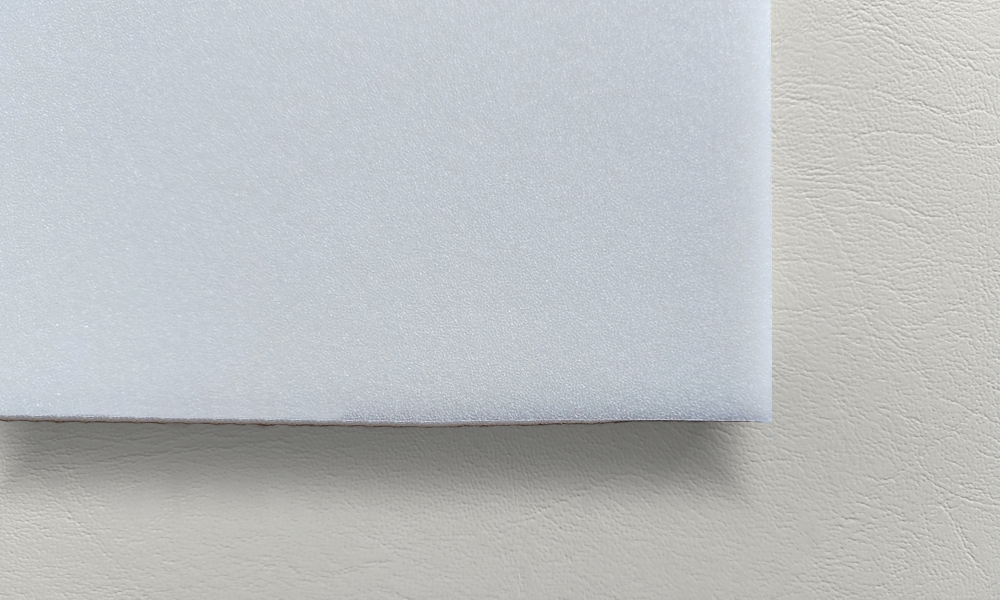

Different backsides

The backside of a laminated foam composite can optionally be equipped with an additional textile or with a film in order to optimize the processing properties of the overall product. These backsides can be tailored to the specific requirements of our customers.

Laminations - Short and compact

- Optimum quality thanks to in-house flame lamination

- Custom-made production and contract manufacturing

- Roll-by-roll lamination of stock items with individual foams and backsides

- Very large selection of foam thicknesses and qualities

- Large selection of backsides

Perforations

Our profile

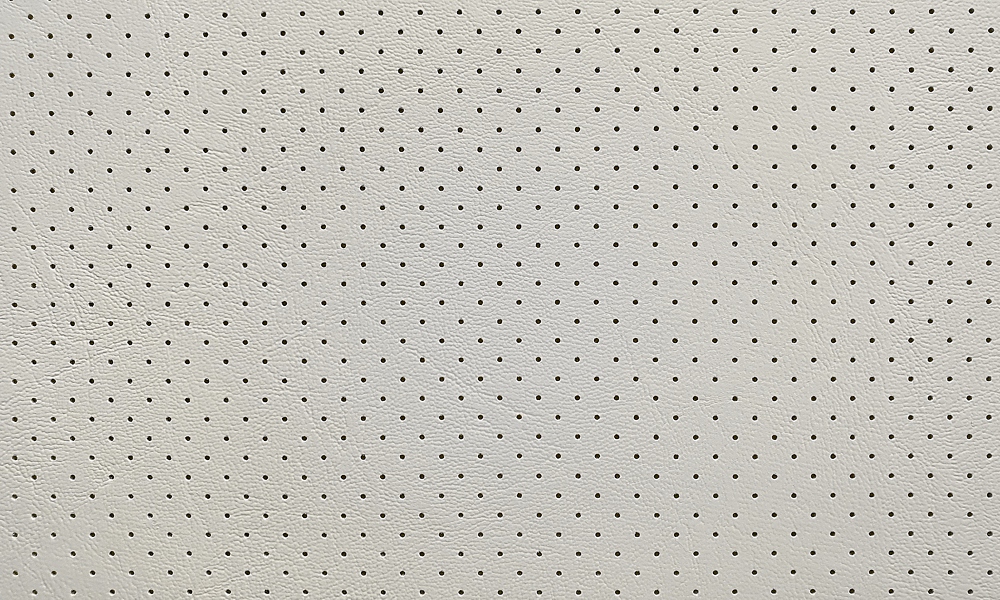

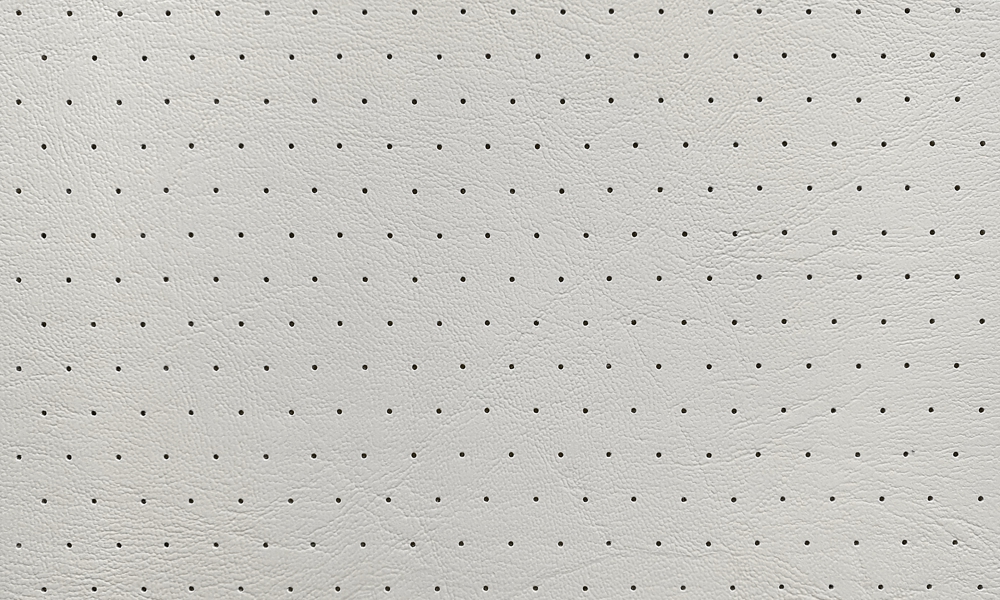

Our in-house perforation system enables us to refine stock items roll by roll. The perforation improves the air circulation and breathability of the material and supports the removal of moisture. In addition to the hole patterns WS02 and WS44, other designs and micro-perforation are available on request.

Perforations - Short and compact

- Optimum quality thanks to in-house perforation system

- Improvement of the material's air circulation

- Roll-by-roll perforation of stock items with individual hole patterns

- Large selection of hole patterns + micro-perforation possible

- Custom-made production and contract manufacturing

- Can be combined with all types of laminations

HF Weldings

The principle

HF welding creates a permanent bond between thermoplastic materials that have a molecular, electrical polarity. Both PUR and PVC imitation leather and films are suitable for this process. The components to be joined are positioned between two electrodes in the HF welding device. High-frequency alternating current creates an alternating electrical field between the electrodes, which causes the molecules in the composite materials to vibrate. The resulting frictional heat enables thermoplastic deformation, so that the pressure between the embossing electrode and the press table can firmly join the components together.

Individually customizable design

Depending on customer requirements, our stock items can be finished roll by roll using HF welding in different patterns. You are welcome to ask our sales team about the various designs. Here is a small selection of the most common patterns:

Composite variants

We offer two types of material composites: Firstly, the combination of imitation leather with a soft PVC foam and secondly, an imitation leather-PES nonwoven-film composite. Our sales team will be happy to advise you on choosing the right variant for your specific application.

HF Weldings - Short and compact

- Durable, waterproof material composite with a soft cushioning effect

- Roll-by-roll HF welding of stock items with individual designs

- Large selection of embossed designs

- Two different composite variants

Downloads

Contact

-

Sebastian Päßler

Sales Export

- Phone

- +49 (0) 37468 / 60-306