Performance

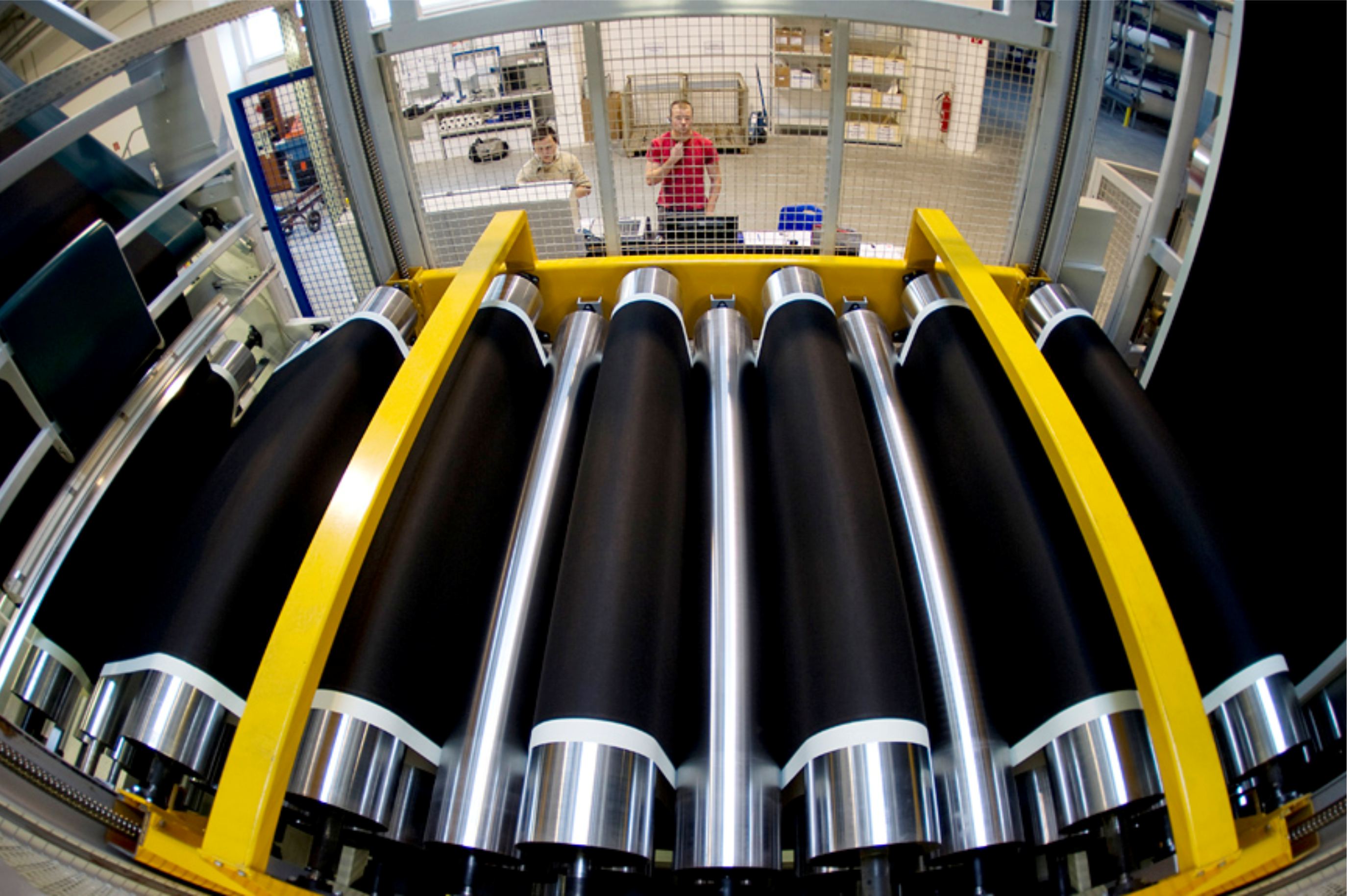

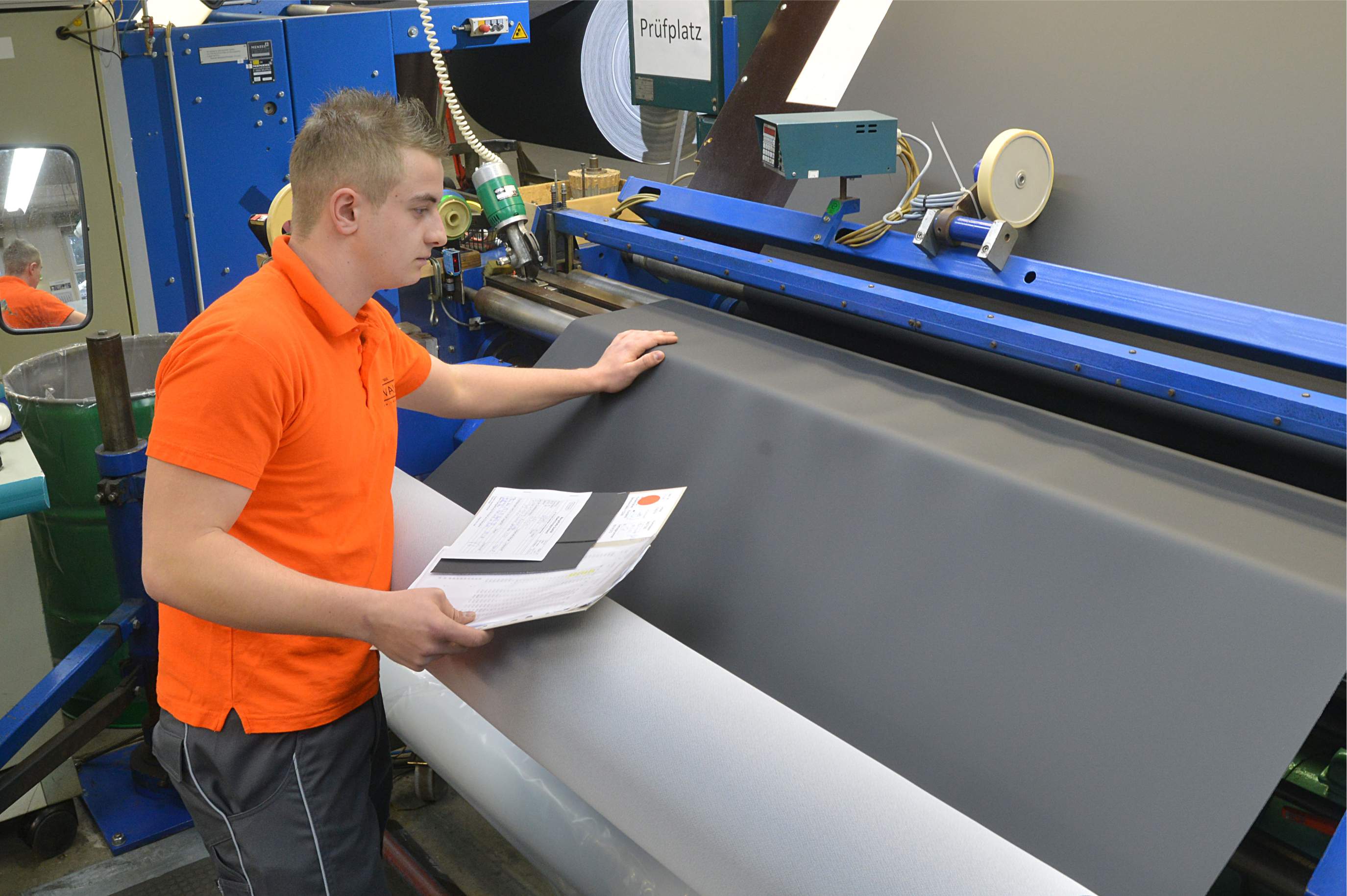

Our Performance

As a coating specialist with decades of experience, we have the most modern systems for coating, finishing and laminating our products. To meet the high quality standards, raw and finished goods are tested in the in-house laboratories using a wide range of procedures. Thanks to the efficient interaction of all our service areas at the production site in Treuen, we produce around 10 million m² of high-quality PVC and polyurethane-based coatings as well as flame laminations every year.

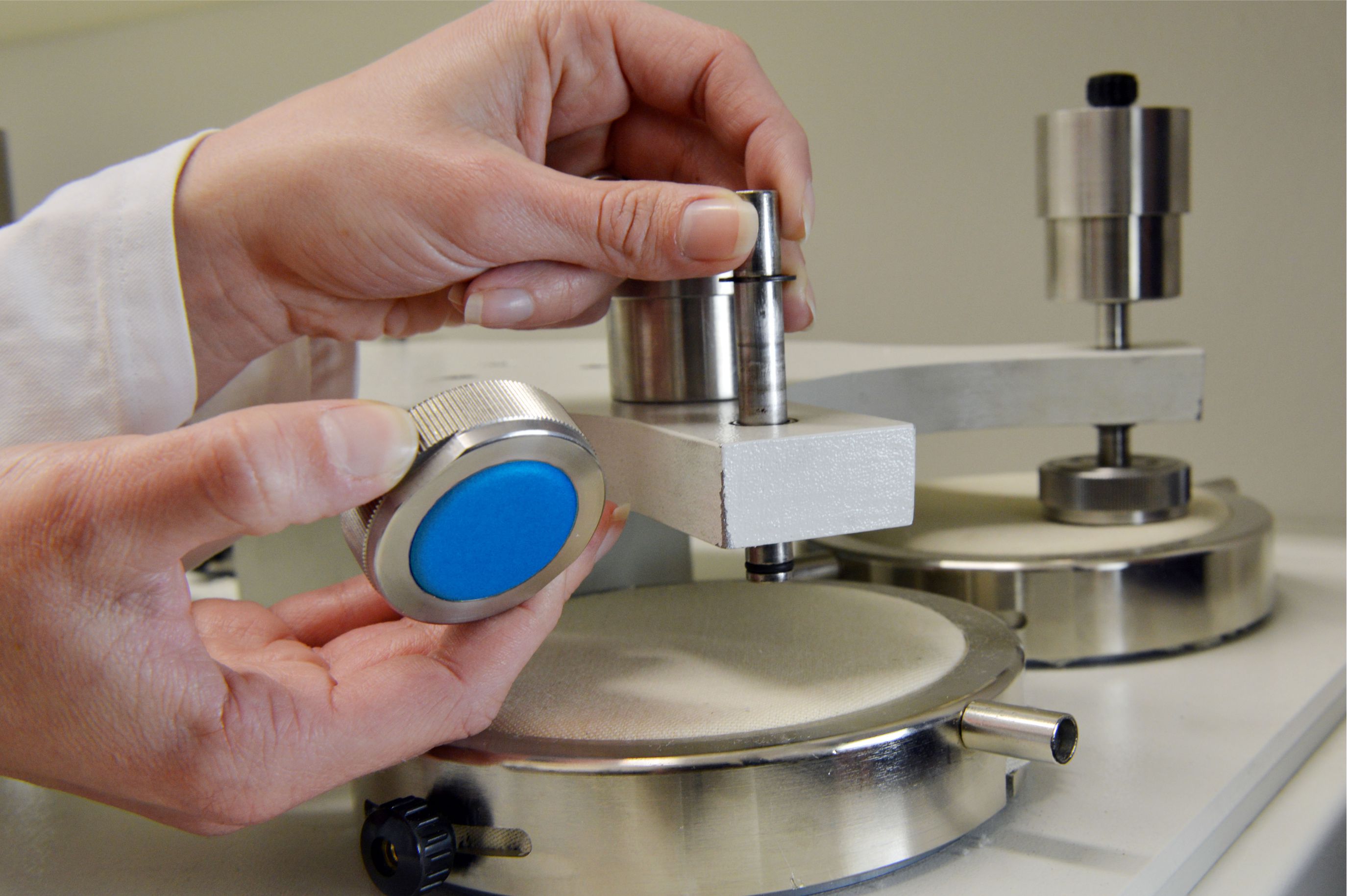

Development

The product ideas and innovations of our product developers are put into practice step by step in the company's own laboratories and at the modern laboratory coating system. We are able to create new developments according to our customers' specifications and offer problem solutions for both standard developments and niche products. The development of new products is of course based on the application of environmentally friendly processes and the use of low-pollutant raw materials. For the human ecology sector, our products are certified according to the OEKO-Tex® Standard 100.

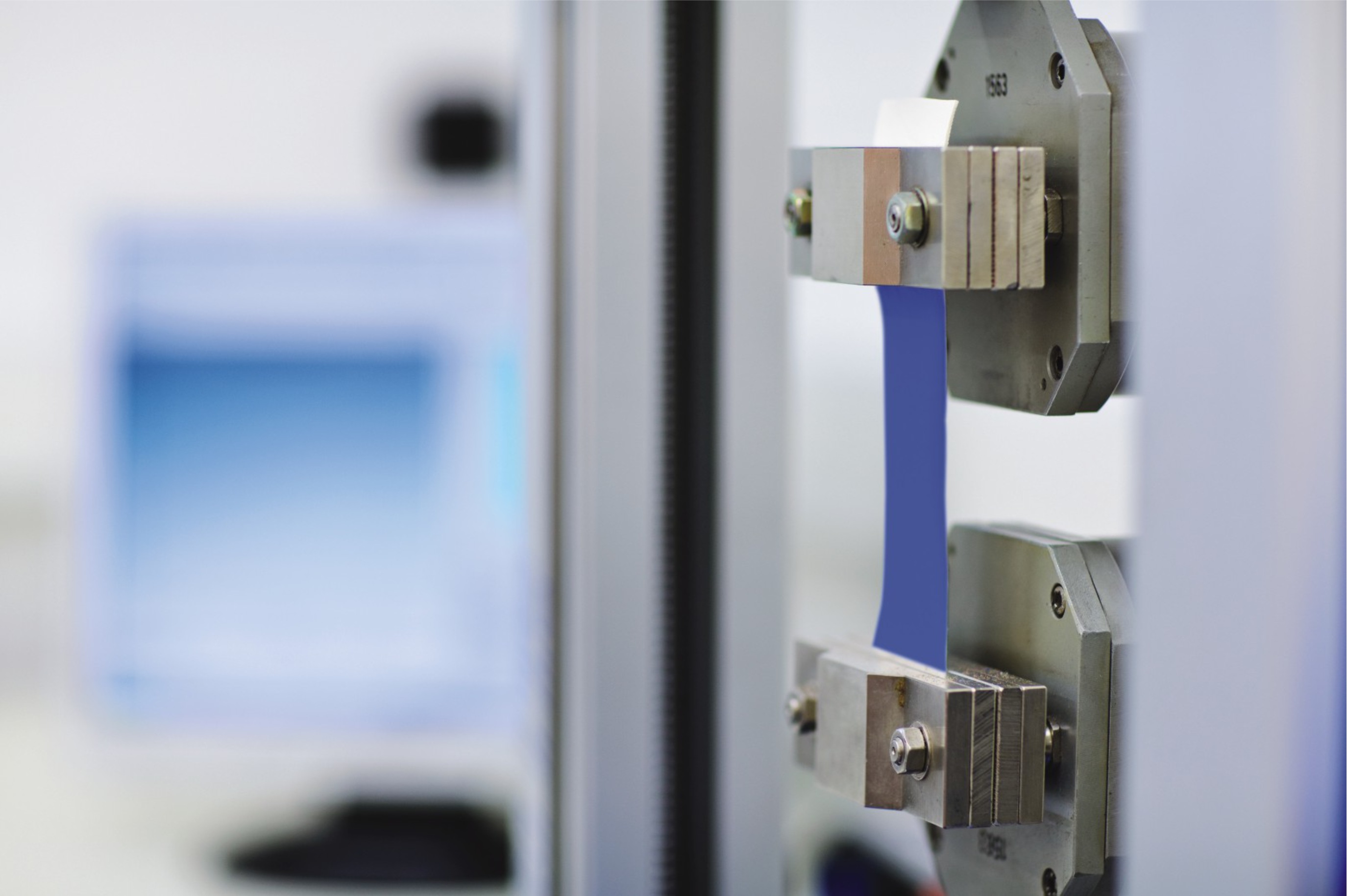

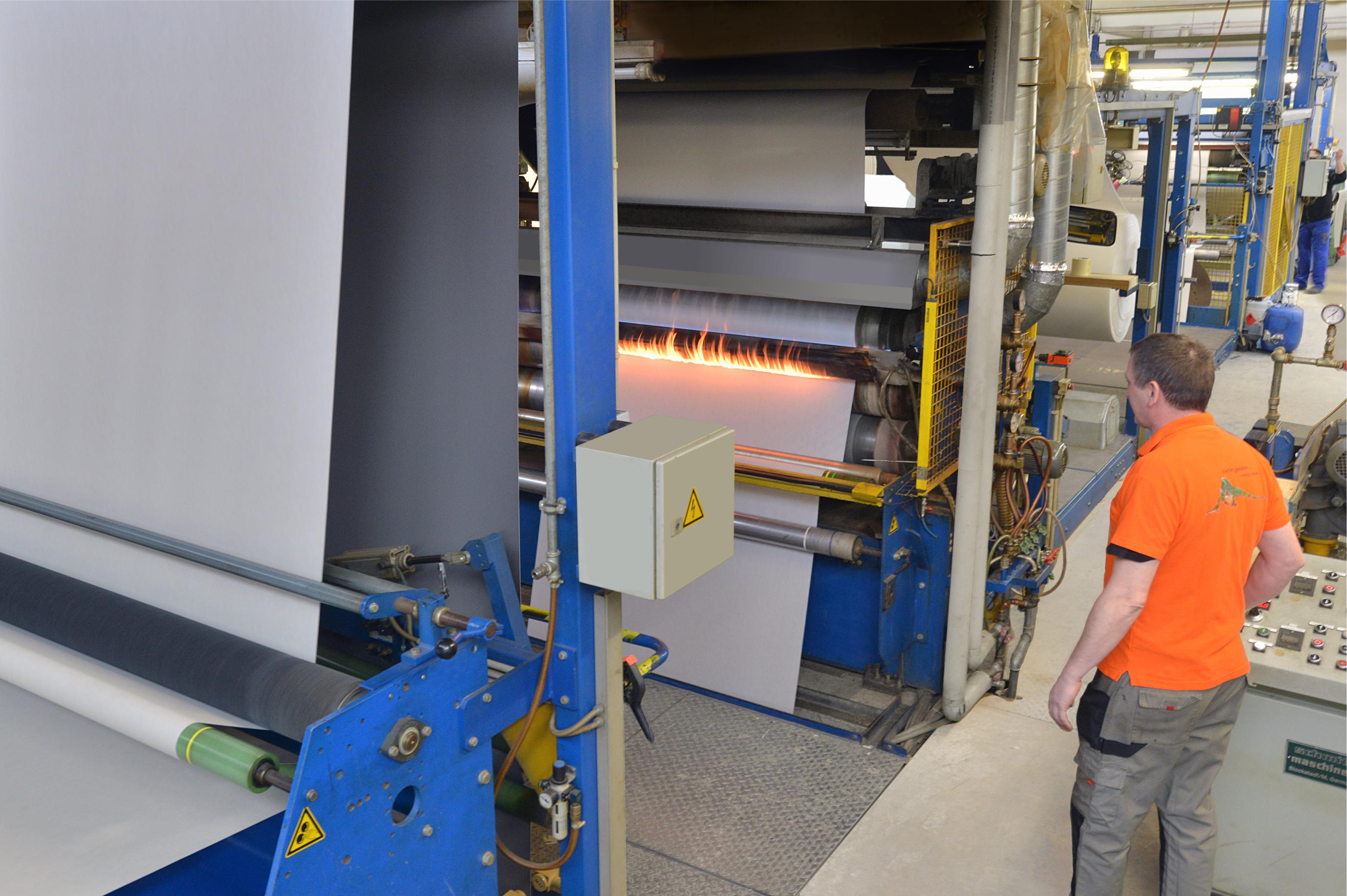

Coating

Our high-performance coating units enable us to work with PUR solutions, aqueous dispersions and PVC plastisols using both direct and indirect coating procedures. The accuracy of these modern coating units means that we can achieve extreme precision both in the lowest weight range and for coatings with densities of more than 1000 g/m². That's why we offer our customers a very extensive product range.

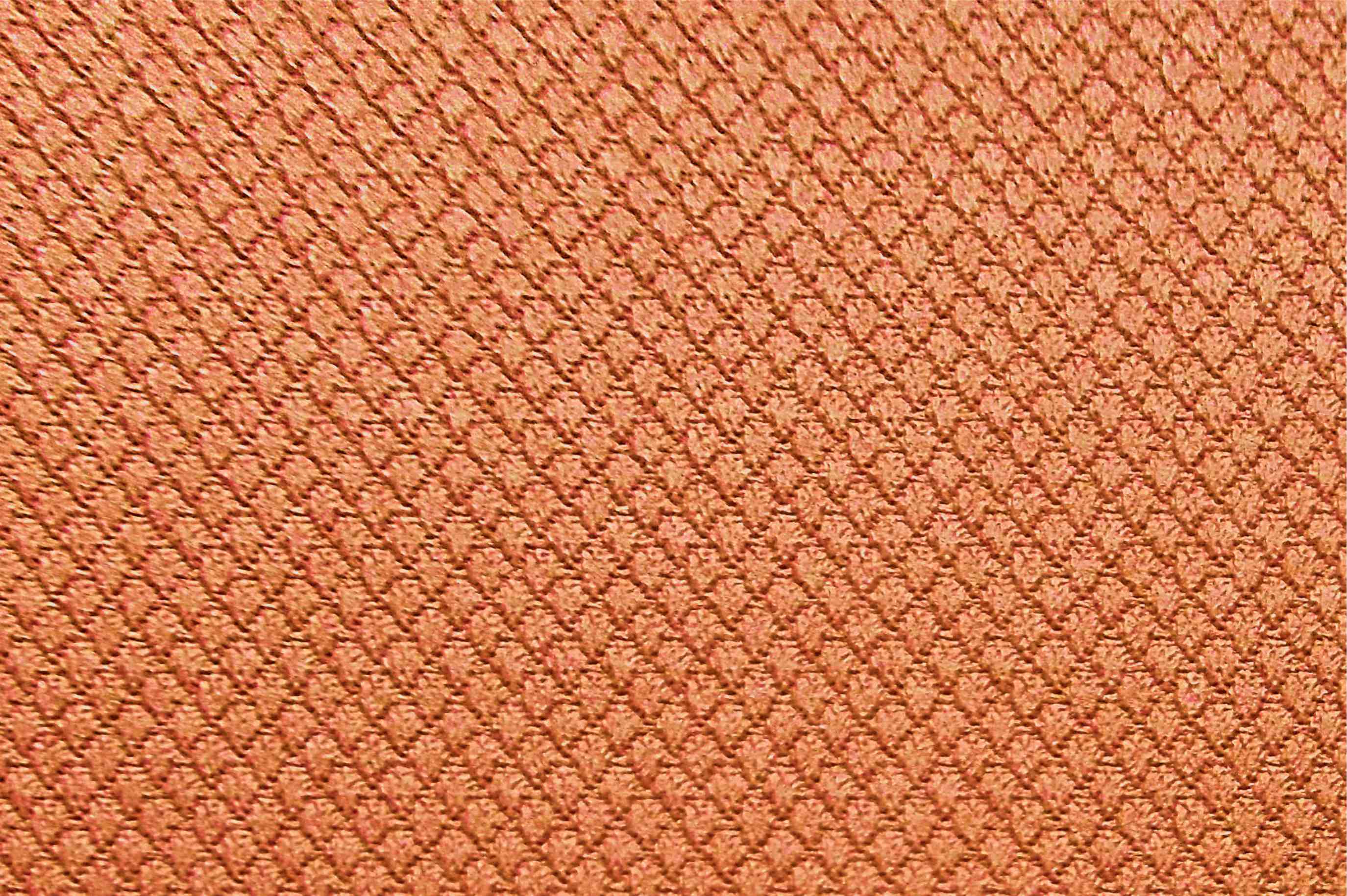

Finishing

In the field of finishing, we have many years of experience in the application of watery printing and lacquering systems as well as special know-how in matching imitation leather to genuine leather in terms of colour and gloss. We are able among others to implement genuine leather embossing on our imitation leather. But we can also draw on a large portfolio of printing and embossing rollers for the production of realistic textile and technical surfaces. The collection comprises a total of more than 500 rollers. This gives us enormous variation possibilities in the development and implementation of customer-specific surfaces.

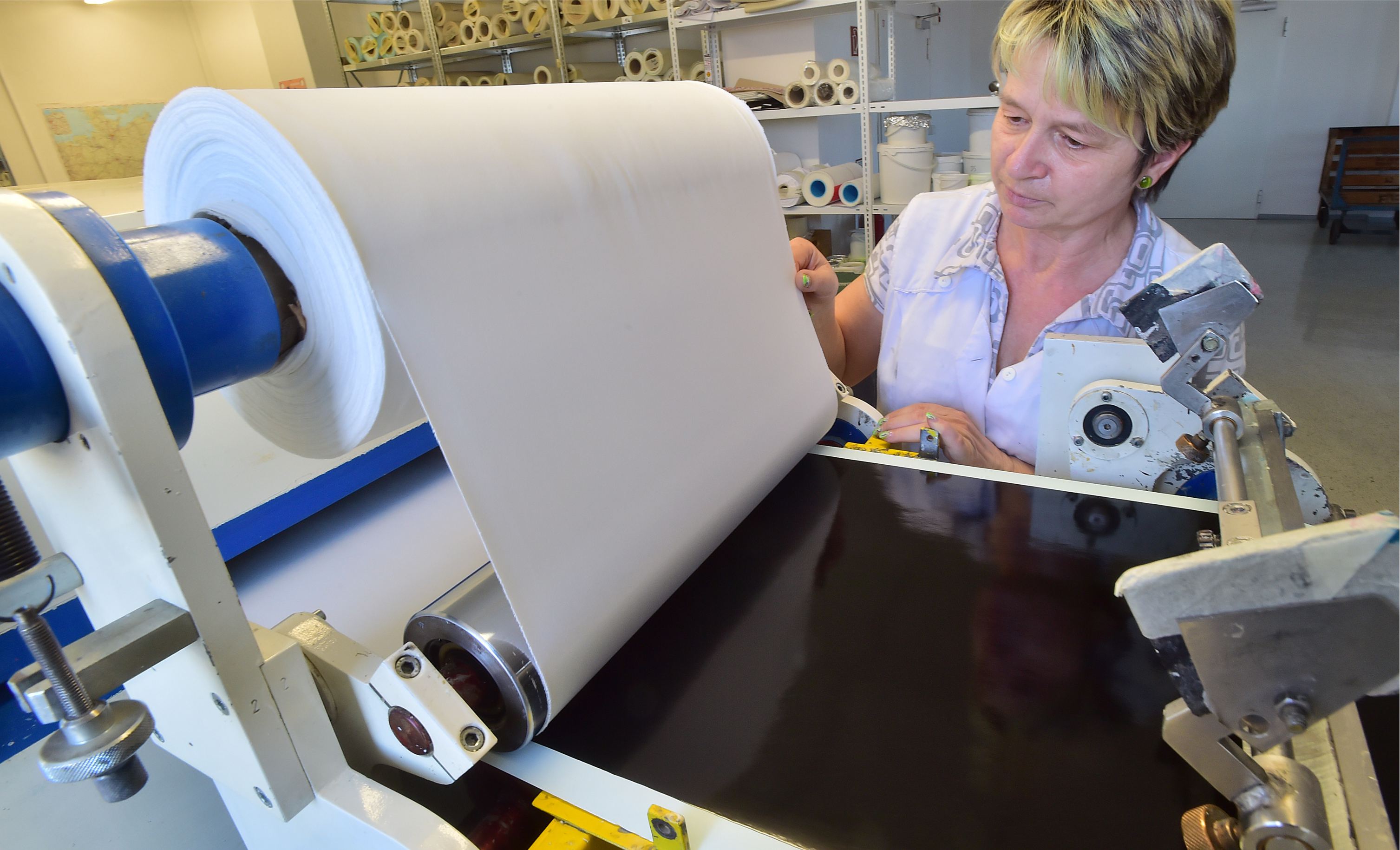

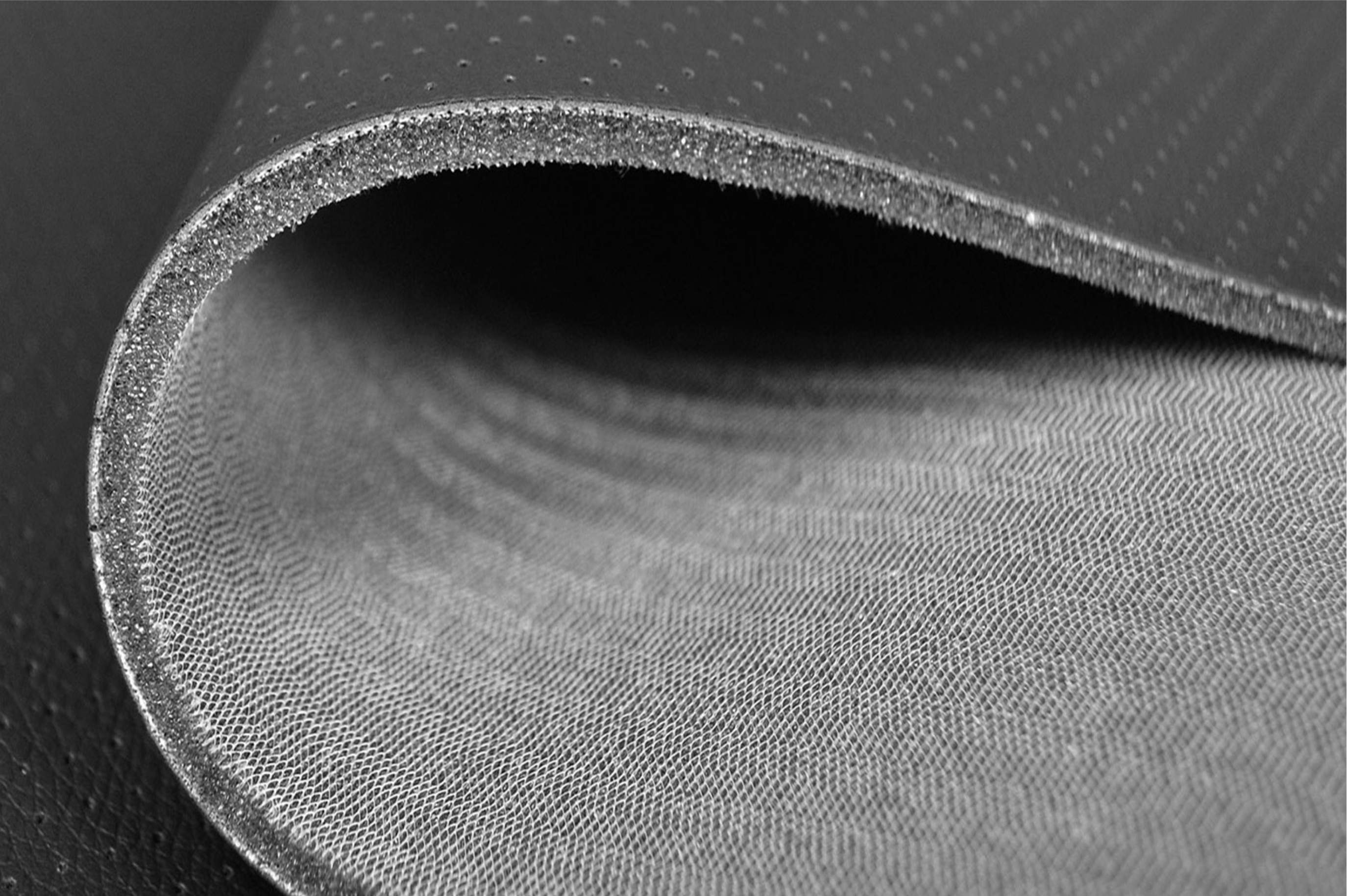

Lamination

Flame lamination is a useful addition to our range of coating services. This enables us to offer complete products, especially for applications in vehicle interiors. Moreover, we work for a wide range of applications, such as laminating materials for gloves and medical products through to articles for thermal insulation.